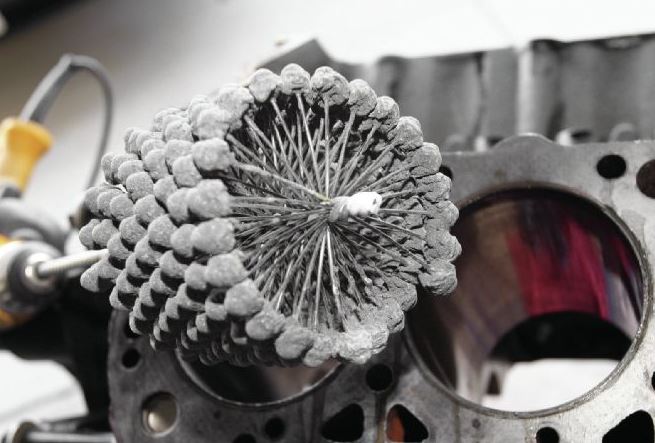

Ball Hone Cylinder Walls

Future cylinder honing will not require as much oil as the first was with a new ball hone.

Ball hone cylinder walls. How to use a ball hone to prepare your cylinder walls. All that s needed is a new set of rings a ball or dingleberry hone is quite enough. As said above the most important things are selecting the right hone and then using it in a way that will create a 45 degree crosshatch pattern on your cylinder wall. For the first use of a new ball hone lubricate the ball hone and bore walls completely several times as the ball hone itself will absorb some of the oil.

But a bore job done correctly requires a few thous of material left so a proper honing job finishes and sizes the bore correctly. A cylinder hone is always produced and used in an oversize condition. Always allow the ball hone to come to a stop while keeping the up and down motion then compress the stones and remove. Removing material is a no no and it can be all too easy to remove material with a stone hone.

Brush research flex hone cylinder hone gb series silicon carbide abrasive 3 1 4 83 mm diameter 240 grit size 4 9 out of 5 stars 496 27 59 27. Wipe and lube generously to clean your cylinder wall you should be able to see the finish and crosshatch easily. The degree of oversize creates pressure and a soft cutting action on cylinder walls.