Ball Hone Vs Stone

If you have any other questions feel free to call our tech services department at 800 533 8010.

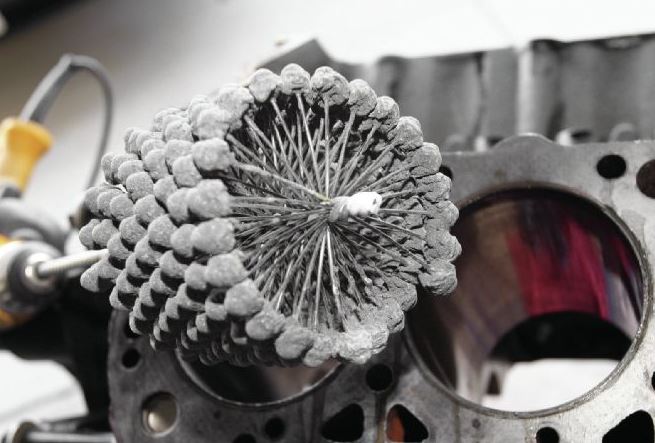

Ball hone vs stone. Of course if it is to far out shape the bore job is next. Ball hones provide a great surface finish and will make your next re ring job a success. Use lots of honing oil and hone for 10 to 45 seconds per cylinder. Today we are going to discuss the differences between the brm flex hone or ball hone and the 2 or 3 stone hone.

The ball hones follow the wavy shit that is worn in the block. So lets see how it holds up against the flex hone https www face. Ball hone how to get the perfect finish for piston ring sealing the ball hone is self centering self aligning to the bore and self compensating for wear. What we call a rigid stone hone is the way to true up the cylinders only if a tweek is all that is needed.

3 stone hone vs a flex hone the biggest advantage of a stone hone is that it will cut large amounts of material. For that 4 030 diameter use the 4 1 8 ball hone with 320 grit bg 418320. Run this tool at around 350 400 rpms. This is a 4 1 8 ball hone with 320 grit.

The rigid stone hone is gear fed like a rack and pinion feed for the stones.