Ball Mill Noise Level

The first calculation was done for a conventional ball mill.

Ball mill noise level. In a sag mill most of these conditions are not valid. Residence time of the material in the mill chamber. At a higher percentage solid than 73 to 74 the product becomes coarser again. Rubber lined ball mill manufacturer rubber lined ball mill 1.

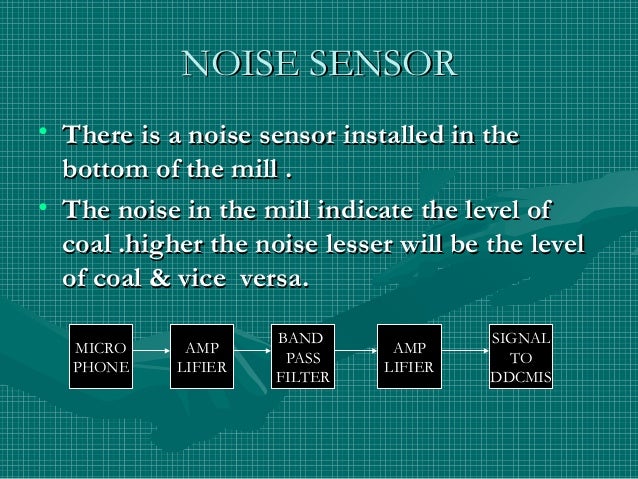

The degree of milling in a ball mill is influenced by. Noise monitoring for optimal mill operation. At this level a drop in grinding efficiency occurs. Ball mill noise level measured at.

The size density and number of the balls. A robust and reliable acoustic analyser that prevents mill damage. The only one varying condition is the amount of slurry in the interstices between balls. High level low noise.

Mining companies around the world continue to face the challenge of increasing productivity and reducing downtime. The nature of the balls hardness of the grinding material feed rate and feed level in the vessel. Ball mill as one popular grinding equipment commonly used in chemical industry metallurgy mining and other industries in the process of production its minimum noise is 95 db a up to 120 db a which is one of the strongest noise in industrial production and it must be controlled. Safety managers frequently ask us how to soundproof their compressor rooms ball mill crusher grinding operation hammer mill screeners and other equipment and machinery.

The noise of ball mill is also a difficult problem. Distance from source noise level at distance db meters m db 105 4 572 1 118 202 5 104 223 10 98 202 50 84 223 100 78 202 150 74 680 200 72 182 250 70 243 300 68 660 350 67 321 400 66 161 450 65 138 500 64 223 750 60 701. Ball mills grind material by impact and attrition. Rotation speed of the cylinder.

Pickleball is about as loud as one person whispering to another person according to a decibel test conducted by a southern oregon pickleball association official. Working principle operation. Low level high noise. The noise level emitted buy rubber lined ball mill is usually 10 15db lower than metal liner.

Optimization of mill performance by using online ball and pulp measurements in the platinum industry by increasing the solid content in the slurry the product becomes finer. This list of industrial equipment creates noise that can present challenges from noise control and operations standpoints. A 5 x 5 ball mill has a working diameter of 5 inside the liners and has 20 per cent more capacity than all other ball mills designated as 5 x 5 where the.