Ball Mill Normally Operate At Speed Of

The center periphery discharge mill has feed reporting from both ends and the product discharges.

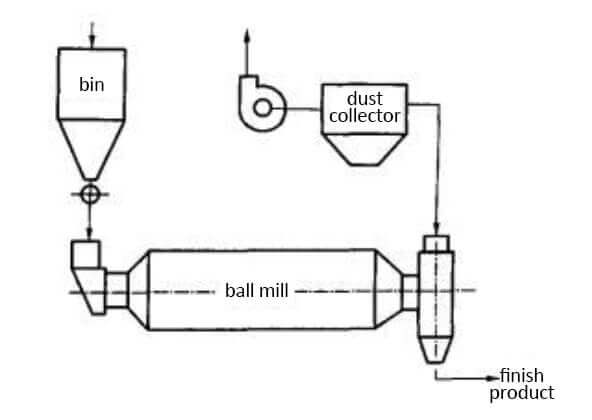

Ball mill normally operate at speed of. Size reduction is done by impact as the balls drop from near the top of the shell. The overflow discharge mill is best suited for fine grinding to 75 106 microns. Dry aerofall mills are run at about 85 of the critical speed. Variables in ball mill operation.

Three types of mill design are common. Eric zhang 40 669 views. As can be seen from the. The overall motion of the balls at the end of five revolutions is shown in figure 4.

A ball mill consists of a hollow cylindrical shell rotati. Critical speed cs is the speed at which the grinding media will centrifuge against the wall of the cylinder. Ball mills are generally used to grind material 1 4 inch and finer down to the particle size of 20 to 75 microns. Sag mills of comparable size but containing say 10 ball charge in addition to the rocks normally operate between 70 and 75 of the critical speed.

The diaphram or grate discharge mill keeps coarse particles within the mill for additional grinding and typically used for grinds to 150 250 microns. Dry mills typically operate in the range of 50 70 of cs and most often between 60 65 of cs. Six lifter bars of rectangular cross section were used at equal spacing. The starting point for mill speed calculations is the critical speed.

For an equivalent grind a rod mill uses less steel than a ball mill because of the lower speed and better contact between the media and ore. The mill was rotated at 50 62 75 and 90 of the critical speed. The point where the mill becomes a centrifuge is called the critical speed and ball mills usually operate at 65 to 75 of the critical speed. Below 50 cs too little.

A ball mill critical speed actually ball rod ag or sag is the speed at which the centrifugal forces equal gravitational forces at the mill shell s inside surface and no balls will fall from its position onto the shell. The rod charge must be maintained in good working condition and broken and worn rods must be removed. Rod mills operate at lower speed than ball mills since the rods are rolled and not cascaded. Use our online formula the mill speed is typically defined as the percent of the theoretical.

Ball mill grinding machine wet ball mill dry ball mill milling machine duration.