Ball Mill Rpm Calculation

Milling operations remove material by feeding a workpiece into a rotating cutting tool with sharp teeth such as an end mill or face mill.

Ball mill rpm calculation. Documents similar to ball mill calculations. The mill critical speed will be calculated based on the diameter above less twice this shell liner width. N speed of ball mill in rpm. Effect of mill speed on the energy input in this experiment the overall motion of the assembly of 62 balls of two different sizes was studied.

A ball mill critical speed actually ball rod ag or sag is the speed at which the centrifugal forces equal gravitational forces at the mill shell s inside surface and no balls will fall from its position onto the shell. The overall motion of the balls at the end of five revolutions is shown in figure 4. No matter how large or small a mill ball mill ceramic lined mill pebble mill jar mill or laboratory jar rolling mill its rotational speed is important to proper and efficient mill operation. How to optimize a 6 pound ball mill to safely and.

The mill turns the jar at about 60 revolutions per minute. That we need a ball mill to grind chemicals. Note this is not the width of a lifter. The optimal ball diameter depending on the by volume the rotation rate was equal to 85 of the critical speed information on ball.

The imagery below helps explain what goes on inside a mill as speed varies. As can be seen from the. Use our online formula the mill speed is typically defined as the percent of the theoretical. Enter the measured mill rotation in revolutions per minute.

Enter the width of a mill shell liner. Mill speed critical speed. To calculate the speed of the mill. Six lifter bars of rectangular cross section were used at equal spacing.

You may use the mill liner effective width calculation to determine this value. Get price and support online. Too low a speed and little energy is imparted on the product. Ball mill calculations scribd.

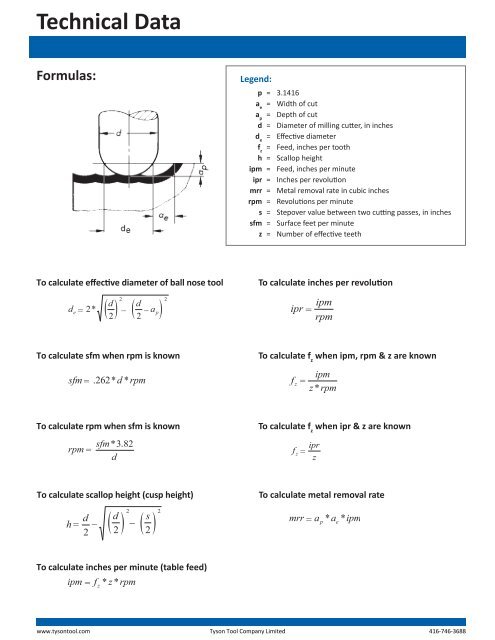

General milling formulas for working with carbide tools engravers end mills and cutters to find using formula sfm surface feet per minute rpm revolutions per minute dia diameter of end mill rpm 3 82 x dia sfm rpm revolutions per minute sfm surface feet per minute dia diameter of end mill.