Ball Nose End Mill Size Chart

As you view the chart you will notice some sizes are linked also.

Ball nose end mill size chart. Each end mill has flutes on its cutting head that carry the removed material away from the workpiece to prevent damage to the end mill or workpiece. Square end mills are commonly used for 2d and 2 5d parts where flat bottoms and vertical walls define the design. Also called ball nose end mills they are used extensively in manufacturing tools dies and machining complex three dimensional contours with a smooth finish. This table shows end mill diameter sizes for inch metric and micro milling bits from 0 005 to 1.

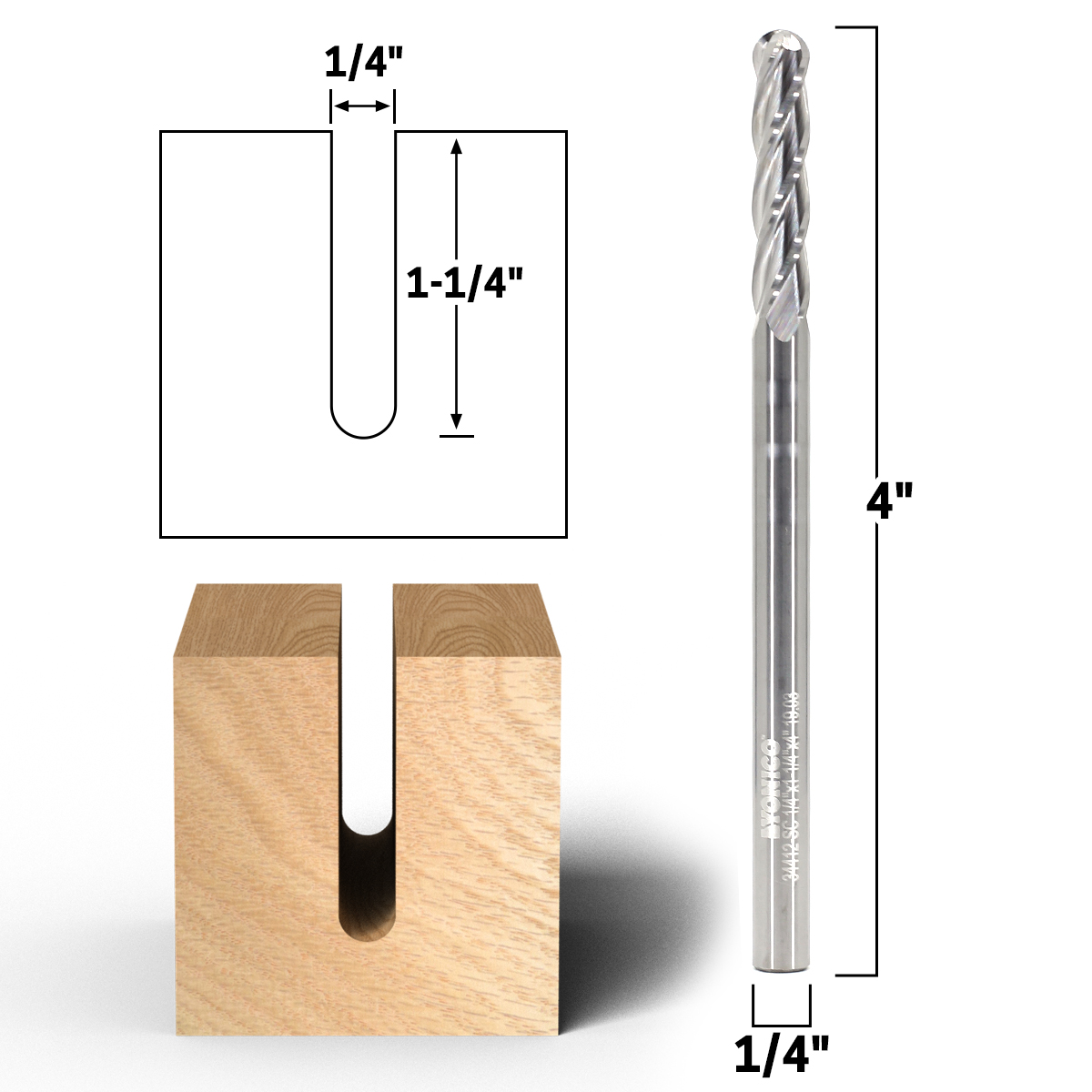

You can find this in the tab called technical info and the link end mill sizes. Ball end mills also known as ball nose end mills are used for milling contoured surfaces slotting and pocketing. Ball end mills create a round bottomed groove in a workpiece. Titan tc11609 solid carbide end mill regular length 4 flute ball nose 30 degree helix altin coated 9 64 size 3 16 shank diameter 2 overall length 9 16 cutting length 5 0 out of 5 stars 1 misc.

End mill sizes many people have asked that we create a chart showing all of the end mill diameters. Hqmaster cnc router bit 1 8 shank ball nose end mill 2mm cutting dia. This will take you to a page where all of that diameter s end mills are listed. Square end mills cut a flat bottomed groove with 90 inside corners.

2 flute spiral upcut milling cutter engraving carving tool set tungsten steel 17mm cel 38 5mm oal for mdf acrylic wood pvc 10pcs. Made of solid carbide these end mills are harder stronger and more wear resistant than high speed steel for the longest life and best finish on hard material. So we have done that and want to make all of our customers aware. They do a nice job of getting in the nooks and crannies of contours without disturbing the surrounding material.

A ball end mill is constructed of a round cutting edge and used in the machining of dies and molds. Some inch sizes below are linked below to make it. End mill size chart pdf the above link provides a printable and downloadable chart of the table below. When one end wears out switch to the opposite end for two times the life of a standard carbide end mill.

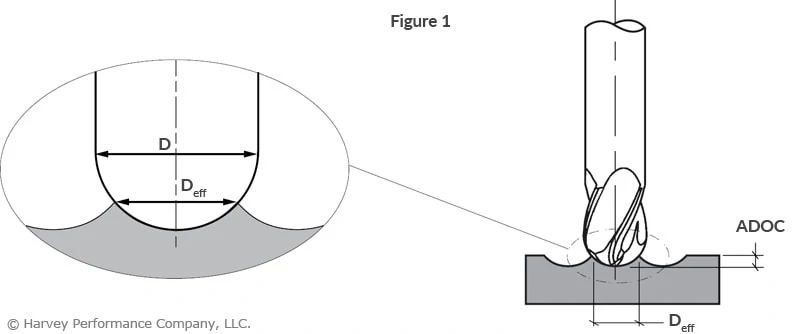

Ball nose end mills are known to be used for contoured or organic shapes. Ball end mills are very durable and come with an array of surface coatings tailored for milling a wide range. Ball nose milling without a tilt angle.