Ball Nose End Mill Speeds And Feeds

Milling speeds and feeds charts the most important aspect of milling with carbide end mills is to run the tool at the proper rpm and feed rate.

Ball nose end mill speeds and feeds. Fill in the blocks shaded in blue with your application information. We have broken these recommendations down into material categories so you can make better decisions with how to productively run your end mills. Martin chick associates cnc programming services. Phone 440 251 4290.

Ball nose milling without a tilt angle. Ball nose finishing mills speed feed calculator instructions. The calculator will automatically provide the necessary speed and feed in the green fields. Speed and feed calculators ball mill finish calculator part spacing calculator g and m code characters standard end mill sizes standard drill sizes drill.

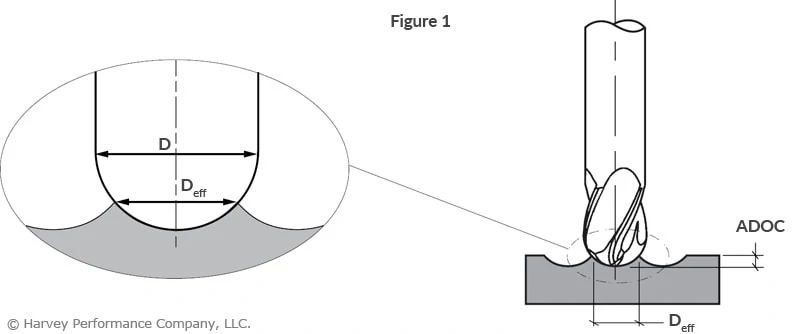

Simply search for your tool number and then click on the orange speeds feeds tab next to the product table. Ball nose end mills are ideal for machining 3 dimensional contour shapes typically found in the mold and die industry the manufacturing of turbine blades and fulfilling general part radius requirements to properly employ a ball nose end mill with no tilt angle and gain the optimal tool life and part finish follow the 2 step process below see figure 1. Speeds feeds solid carbide high performance end mills. In addition to our speeds feeds libraries you can also find specific running parameters directly on our product pages for every tool.