Ball Screw Critical Speed

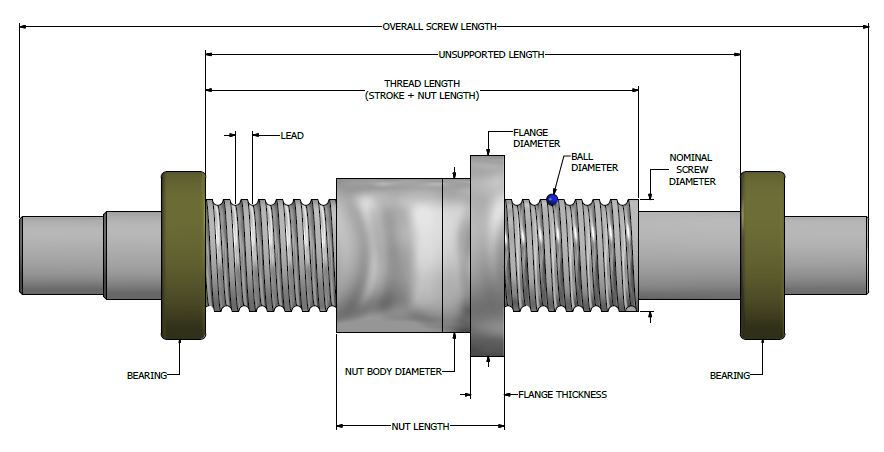

In this calculation length is defined as the screw s.

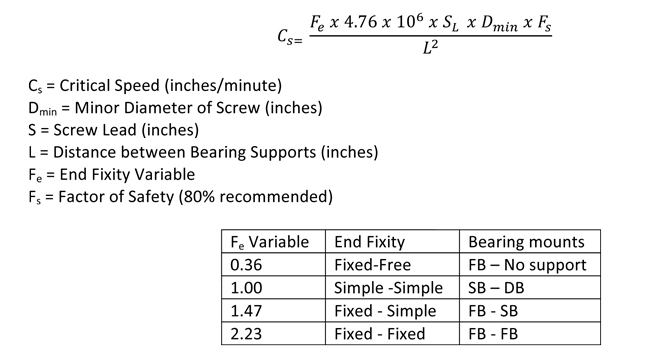

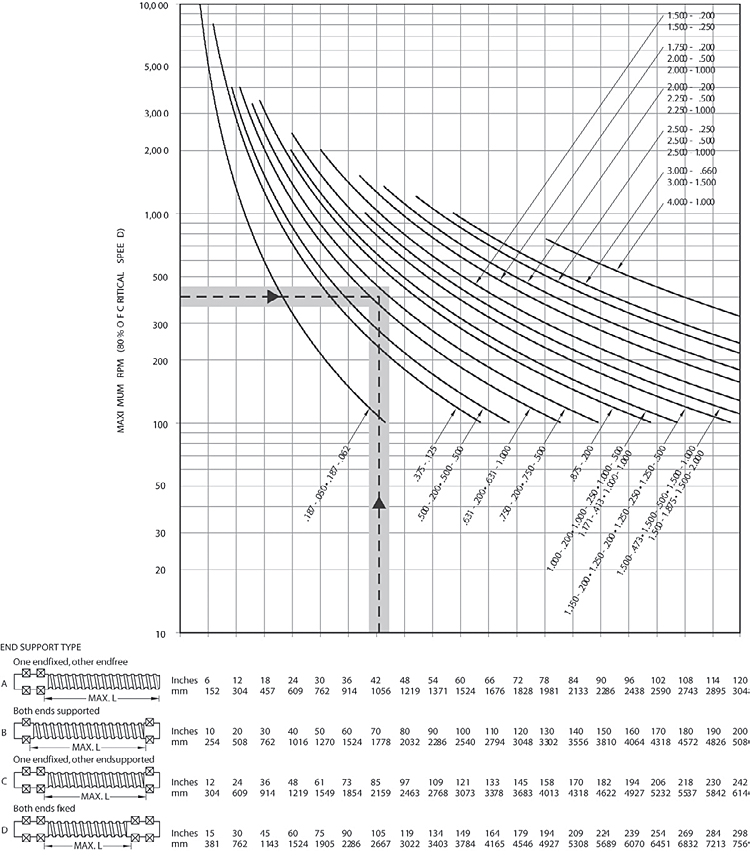

Ball screw critical speed. Take advantage of this critical speed calculator along with the many other various calculators roton has available at your disposal. It can also back calculate to determine the diameter or length based on a specific screw rpm. Nevertheless steinmeyer recommends operating a ball screw only up to a maximum speed not to exceed approximately 80 of the critical speed or to discuss the possibility of higher speed with our engineers. The following formula is used to calculate critical speed in r p m.

L cr unsupported length of ball screw. The critical speed of a ball screw is the first order natural frequency of the screw shaft. The input speed which excites the resonant frequency of a system. N c s 4 76 10 6 d.

As a screw shaft rotates it begins to whip much like a jump rope. Critical speed roton products inc. D n root diameter of ball screw. N critical speed rpm d root diameter of screw inch l length between bearing supports inch c s 0 36 for one end fixed one end free.

N c critical speed. This behavior limits the screw s critical speed. Critical speed critical speed is the lowest rotational speed at which the ball screw shaft is in resonance. The calculator uses the diameter unsupported length and end fixity to determine the approximate rotational speed at which resonance will occur.

The screw will resonate regardless of screw orientation or whether the nut rotates about the screw. Buckling load a shaft under compressive axial load is subject to potential buckling. It is recommended that the maximum axial load on the ball screw be limited to 50 of the buckling load. The speed that excites the natural frequency of the screw is referred to as the critical speed.

Critical speed is essentially the rotational speed at which the ball screw will start to vibrate and introduce excessive oscillation known as screw whip. Of a ball screw be limited to 80 of the critical speed. K factor based on end support bearings. This is heavily dependent on the length of the screw along with the mounting support for the end bearings.

Inch critical speed metric critical speed. The calculation for critical speed takes into account the screw s diameter and length as well as the type of end bearings supporting the screw. The final factor to verify is the critical speed.