Ball Screw Force Calculator

F1 is the vector component tangent to the ballscrew of the force applied by the screw onto the ball bearing.

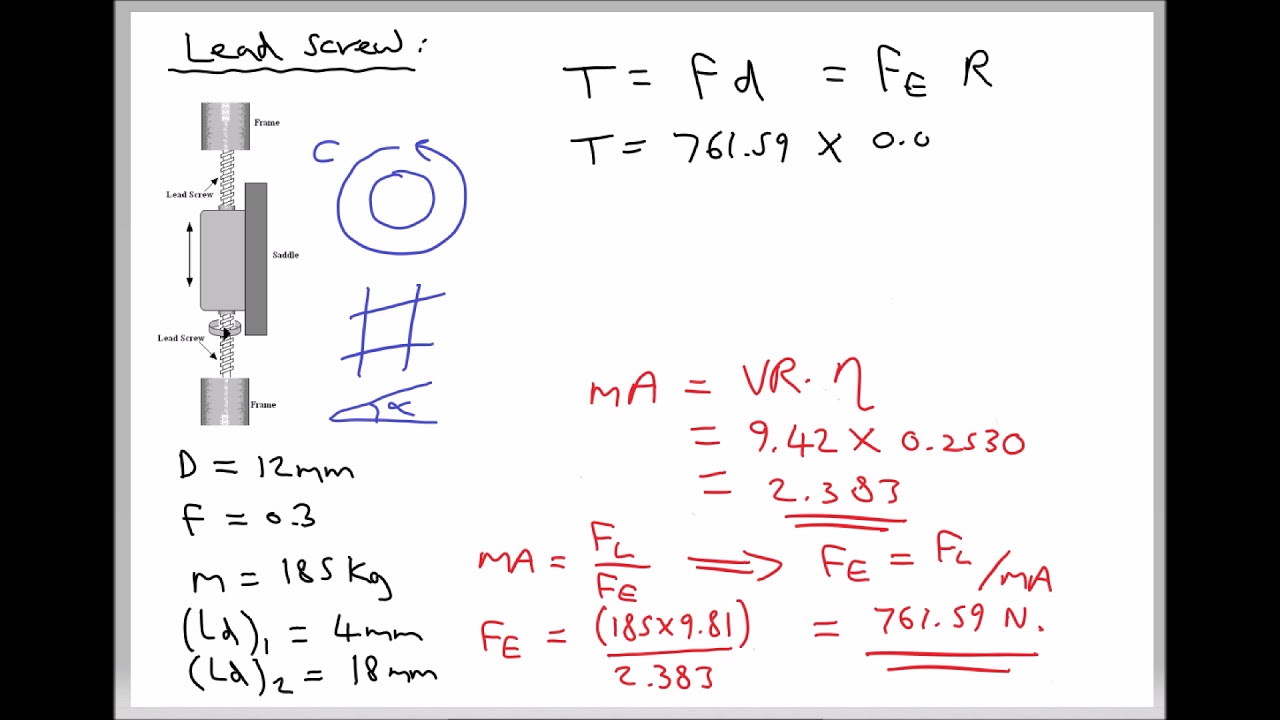

Ball screw force calculator. π ρ λ π ρ λ e l d a ei l n b tr b c 2 2 2 2 2 15 2 60 nc. Additionally based on the list axial clearances of ball screws on p 1893 3 it can be confirmed that the bss1520 with axial clearance of 0 005 or less can satisfy the repeatability requirement of 0 01mm. As well as being able to apply or withstand high thrust loads they can do so with minimum internal friction. Lead screw torque and force calculator.

Torque force x distance rotational force acting on a ball bearing x radius of ballscrew so you can calculate the rotational vector component of force based on torque and the radius of the ballscrew. Critical speed min 1 lb. 1 2 10 has 0 1 lead. T f1 x d 2 where.

Drive torque is primarily influenced by the axial load on the screw and the screw s lead. Ball screw examples of selecting a ball screw high speed transfer equipment horizontal use selection conditions table mass m 1 60kg work mass m 2 20kg stroke length s 1000mm maximum speed v max 1m s acceleration time t 1 0 15s deceleration time t 3 0 15s number of reciprocations per minute n 8min 1 backlash 0 15mm. Ball screw and acme screw linear thrust force lintech manufactures standard positioning actuators systems stages and slides. Ball screw selection 1 selecting overall length of the screw shaft.

Calculate how much linear force a lead screw or ball screw can produce given the torque of a motor the lead or ball screw efficiency and pitch. The axial load is not only the process force drilling punching etc but also includes the force required to move the load. A ball screw is a mechanical linear actuator that translates rotational motion to linear motion with little friction. Me en 7960 precision machine design ball screw calculations 4 13 permissible speed when the speed of a ball screw increases the ball screw will approach its natural frequency causing a resonance and the operation will become impossible.

When designing machinery that uses lead screws it s a common task to try and figure out the size of motor needed to drive a given force with a lead screw. They are made to close tolerances and are therefore suitable for use in. A threaded shaft provides a helical raceway for ball bearings which act as a precision screw. Torque of motor oz in.

F a total axial force n p lead mm η efficiency of ball screw. Ball screw length l max.