Ball Screw Holding Torque

I have a set of 4 ball screws 2 inch diameter by 0 50 one in each corner to lift up a 12 000lb transformer.

Ball screw holding torque. In case of a power loss the motor has no holding torque which causes the load to come crashing downward. T b back driving torque nm f axial load n p screw lead m η 2 reverse efficiency 0 8 to 0 9 for ball screws efficiency when back driving is typically less than the efficiency for normal operation. There are two torques the torque to raise the load and. All ball screw jacks can backdrive and require some means of holding the load such as a brake on the motor.

This calculator will calculate torque given the lead screw parameters and the required force. First calculate the back drive torque which is a factor of the load the screw lead and the screw efficiency. The screw can still function for 2 600 cycles with just one circuit operating. Typically both systems have a mechanical efficiency of 90 percent.

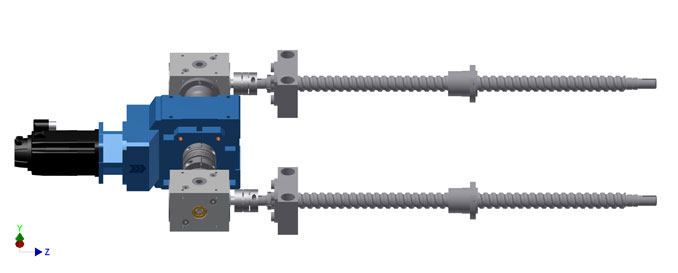

When designing machinery that uses lead screws it s a common task to try and figure out the size of motor needed to drive a given force with a lead screw. Each side will have one motor driving a right angle worm gearbox in the center that will power the two other right angle gearboxes that turn the ball. Ball screws and torque calculations seventofour mechanical op 6 dec 16 00 47. A ball screw with four circuits in normal operation for example might be designed to operate for 209 000 cycles.

A retaining ring grips inside the recess to hold screws in place. Lead screw torque and force calculator. From a practical standpoint holding torque is the sum of the magnetic force exerted by the coils to hold the motor s current position plus the detent torque. Holding torque is typically higher than running torque and is limited primarily by the maximum current the motor can withstand.

Ball end screw holding hex bits when you don t have exact alignment between the fastener and the bit the ball end allows angled entry to turn screws in hard to reach areas. The ball screw lead does have a significant influence on the torque required. Ball end screw holding l key sets these assorted keys have a detent that grips inside the recess to ensure screws wonâ t fall off. The ball end has a detent to grip inside the screw recess and allows angled entry to turn fasteners in hard to reach areas.

Back drive torque t b can be calculated as t b ple 2π where l is the screw lead in inches p is the load in pounds and e is a mechanical efficiency constant.