Ball Screw Torque To Force Calculator

Converting between linear force and torque of a ballscrew.

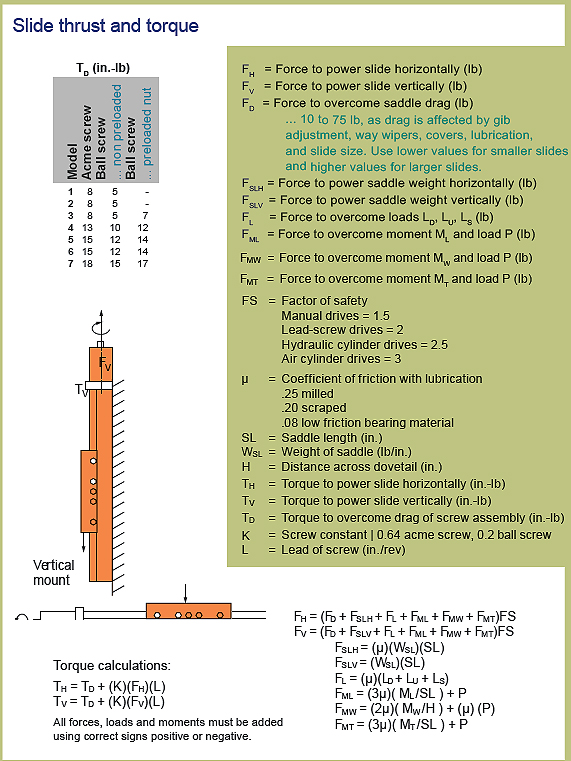

Ball screw torque to force calculator. Ball screw selection 1 selecting overall length of the screw shaft. Ball lead screw motor sizing forms calculate the necessary torque speed stopping accuracy and system inertia important when selecting a proper motor for the application. The energy to lift 20kg vertically 8mm 20kg g 0 008m 1 6j. T p torque due to preload provided by manufacturer nm t f torque due to friction of support bearings and seals provided by manufacturer nm drive torque is primarily influenced by the axial load on the screw and the screw s lead.

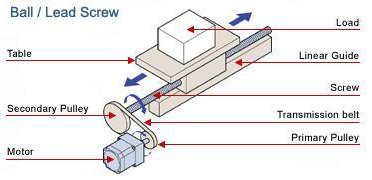

This calculator will calculate torque given the lead screw parameters and the required force. A ball screw is a mechanical linear actuator that translates rotational motion to linear motion with little friction. Formulas for acceleration torque and acceleration force are average values only for the time period values used. A threaded shaft provides a helical raceway for ball bearings which act as a precision screw.

F a total axial force n p lead mm η efficiency of ball screw. As well as being able to apply or withstand high thrust loads they can do so with minimum internal friction. When designing machinery that uses lead screws it s a common task to try and figure out the size of motor needed to drive a given force with a lead screw. They are made to close tolerances and are therefore suitable for use in.

So a force of 0 26n around a circle of 1m radius is 2 pi 1 0m 0 26n 1 6j. Actual peak torques and peak forces to accelerate can be several order of magnitude greater than formula values for short periods of time. If you have a torque of 0 26nm then one turn of the motor is like providing a force of 0 26n at a radius of 1m and energy is force distance. Ball screw length l max.

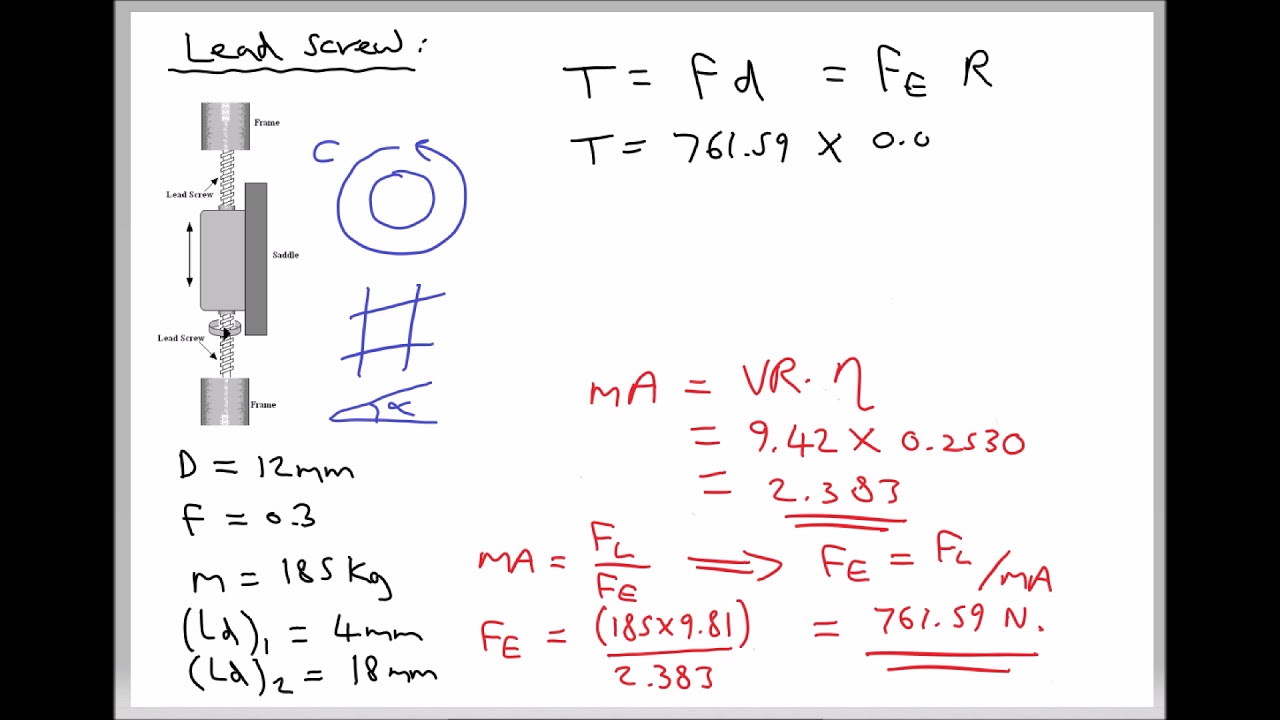

Linear force calculate how much linear force a lead screw or ball screw can produce given the torque of a motor the lead or ball screw efficiency and pitch. Friction breakaway accel oz in please enter in information above in order to calculate the screw linear thrust force used in a positioning system. Additionally based on the list axial clearances of ball screws on p 1893 3 it can be confirmed that the bss1520 with axial clearance of 0 005 or less can satisfy the repeatability requirement of 0 01mm. Lead screw torque and force calculator.