Ball Valve Handle Orientation

Consult factory for throttling service.

Ball valve handle orientation. 2 under certain conditions throttling flow in the near closed position can destroy the valve seats. The choice of flow pattern or valve ball porting t port vs l port provides specific options. Ball valve lever handle for ba 100 150 series ball valves. It has worked perfectly.

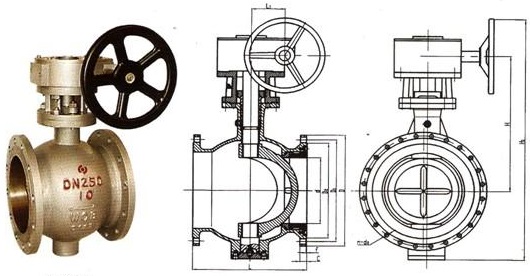

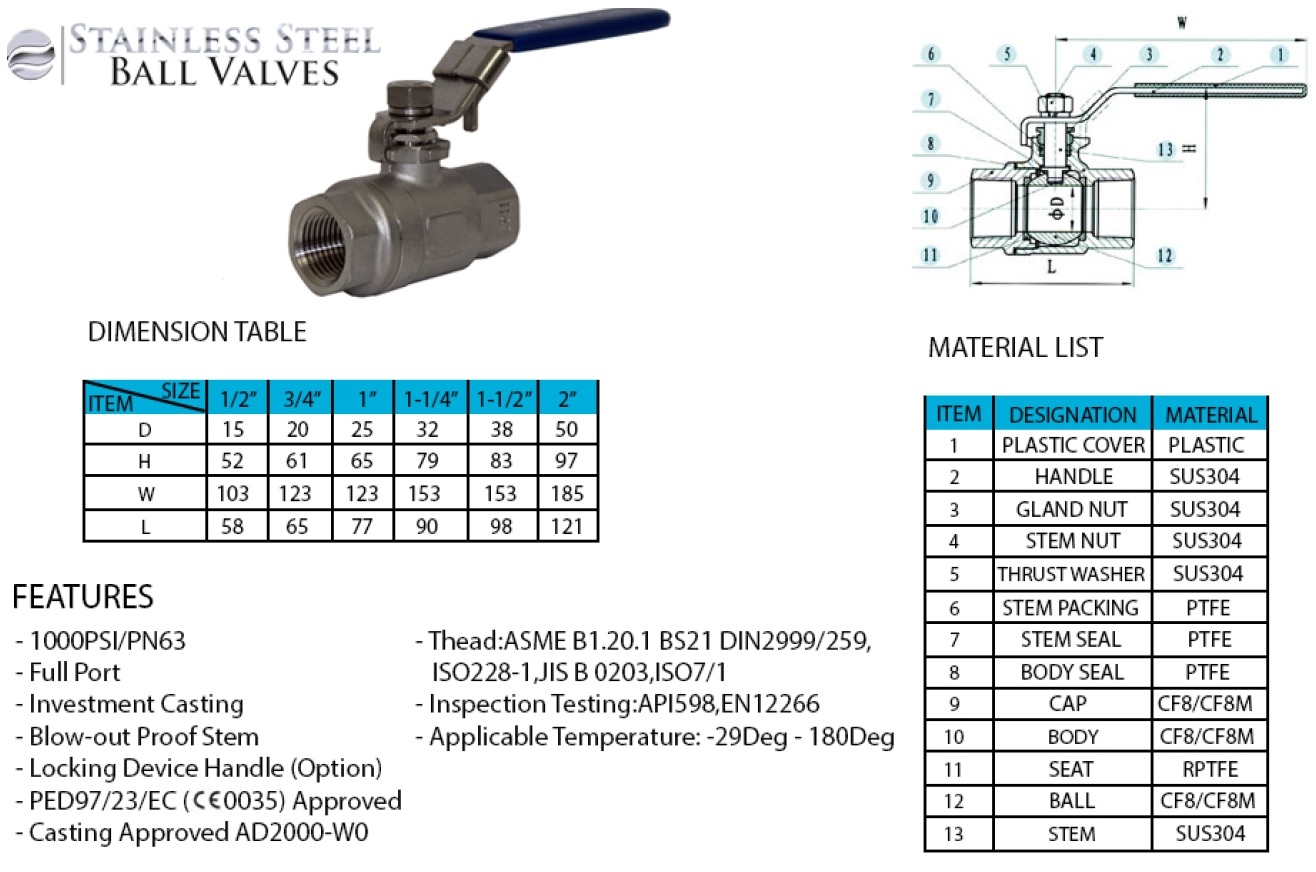

The ball valve is an inexpensive alternative to other valves. Ball valves use a metal ball with a hole bored through the center sandwiched between two seats to control flow. 1958 develops the ball valve and becomes the first world s first supplier of full bore split body type ball valves 1965 creates v bore control valves 1973 launches om ball valves which have since become well recognized as a key industry benchmark 1978 gratite seated ball valves designed and patented 1993 metaltite seated ball valves. Three way ball valves simplify gas and fluid flow control.

The handle indicates the ball port direction. I installed a brass ball valve about 13 years ago with the handle pointing against the flow when in the on position. My valve is female by female so the direction did not matter when assembly the piping. Used in many hydrocarbon process applications ball valves are capable of throttling gases and vapors and are especially useful for low flow situations.

These valves are quick opening and provide a very tight closure on. The flow direction of ball valves can be either bidirectional or unidirectional depending on its seat design and working conditions. This post looks at design differences between l pattern and t pattern flow plus how handle position and range of rotation combine with porting to control flow. A ball is round so direction does no matter.

1 ball valves are designed to be opened by rotating the lever handle in a counterclockwise direction and closing in a clockwise direction. 99 6 50 item 13 99 13 99.