Ball Valve Run Torque

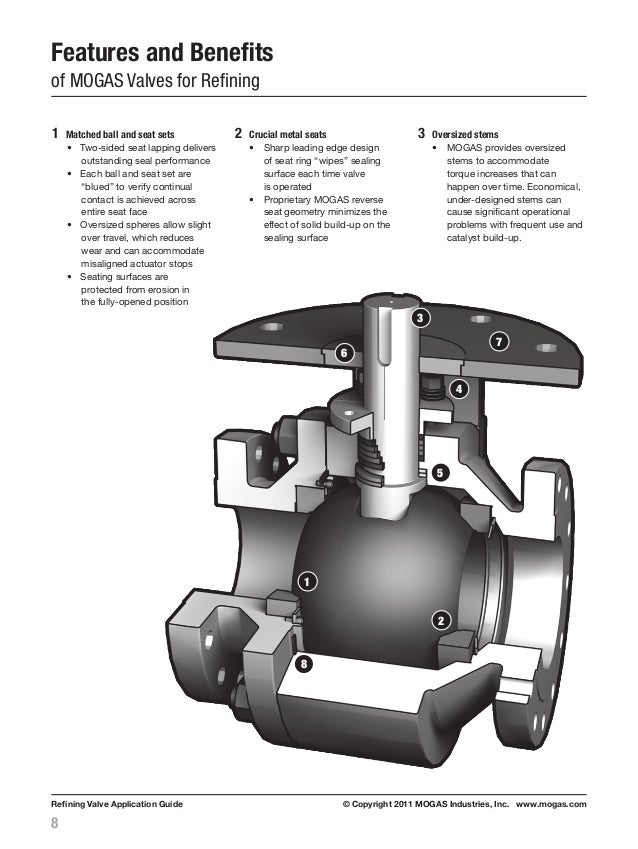

A safety factor above tested breakaway torque has been introduced in these tables to allow for the valve torque increase during the lifetime of the seats from deposits on seats and ball.

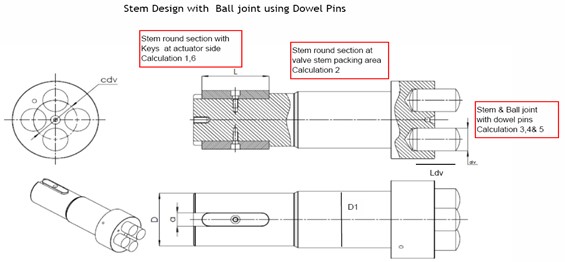

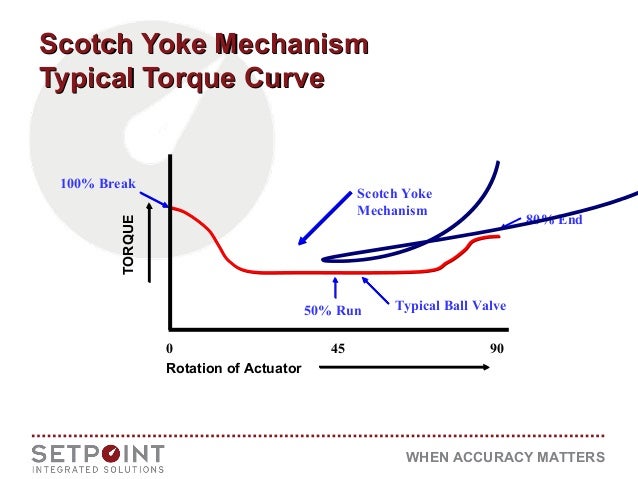

Ball valve run torque. Decreases this torque is known as the run torque at the end of the stroke as the ball and seats are returned to full contact the torque again increases but to an amount less then the valve breakaway torque this torque is known as the valve ending torque. So ball valve will often have a mast max allowabe stem torque and also bto break to open torque required to intiate opening rto run to open the torque required to complete the majotity of the 90 operation and the eto end to open torque required to fully open. Large trunnion ball valves. Etc closing torque.

Actuator torque outputs are tabulated for electric and pneumatic actuators. Torque the rotation of the ball requires a certain turning moment or torque which depends upon factors such as pressure drop and fluid flow velocity. Class 150 and 300 am c and tbzm c series valves with h ptfe packing are certified to 100 ppm maximum fugitive emissions. The valve stem rotates a metal ball with a hole drilled in it through a quarter turn or 90 degrees to open and close the valve.

Not only on torque but also on valve service life. The real valve torque value can be higher depending upon the following listed factors as these factors can drastically increase or decrease the torque. The values have been selected on the basis of breakaway torque of the valve. When being used with rack pinion pneumatic spring return actuators a 0 70 multiplier may be applied to the ball valve torque.

For 150 300 sctbm utbm series valves on pages 4 5 torque values are for both non firesafe and firesafe configurations. Corrosion scale build up on the ball or other service conditions can drastically alter torque requirements and should be given consideration when selecting actuation or automation. 50 of stated bto torque mast maximum stem torque average guide based on floating ball and smaller size trunnion ball valves. 85 of stated bto torque rtc running torque.

The re seat torque is approximately 75 or three quarters of the breakaway torque. For regular bore trunnion valves use the torque for the next smallest full bore valve. The run torque is approximately 50 or one half of the breakaway torque. Due to the variable operating torque of a ball valve when scotch.

The torque needed to keep the ball moving through it s travel. Please advise if any of the following factors are applicable. Media factors are also provided in the tables at the end of this bulletin. Formulas used to calculate values of below mentioned torques based on bto value.

The torque required to reseat a closing valve. Bto values are at maximum rated differential pressure as per valve class at ambient temparature.