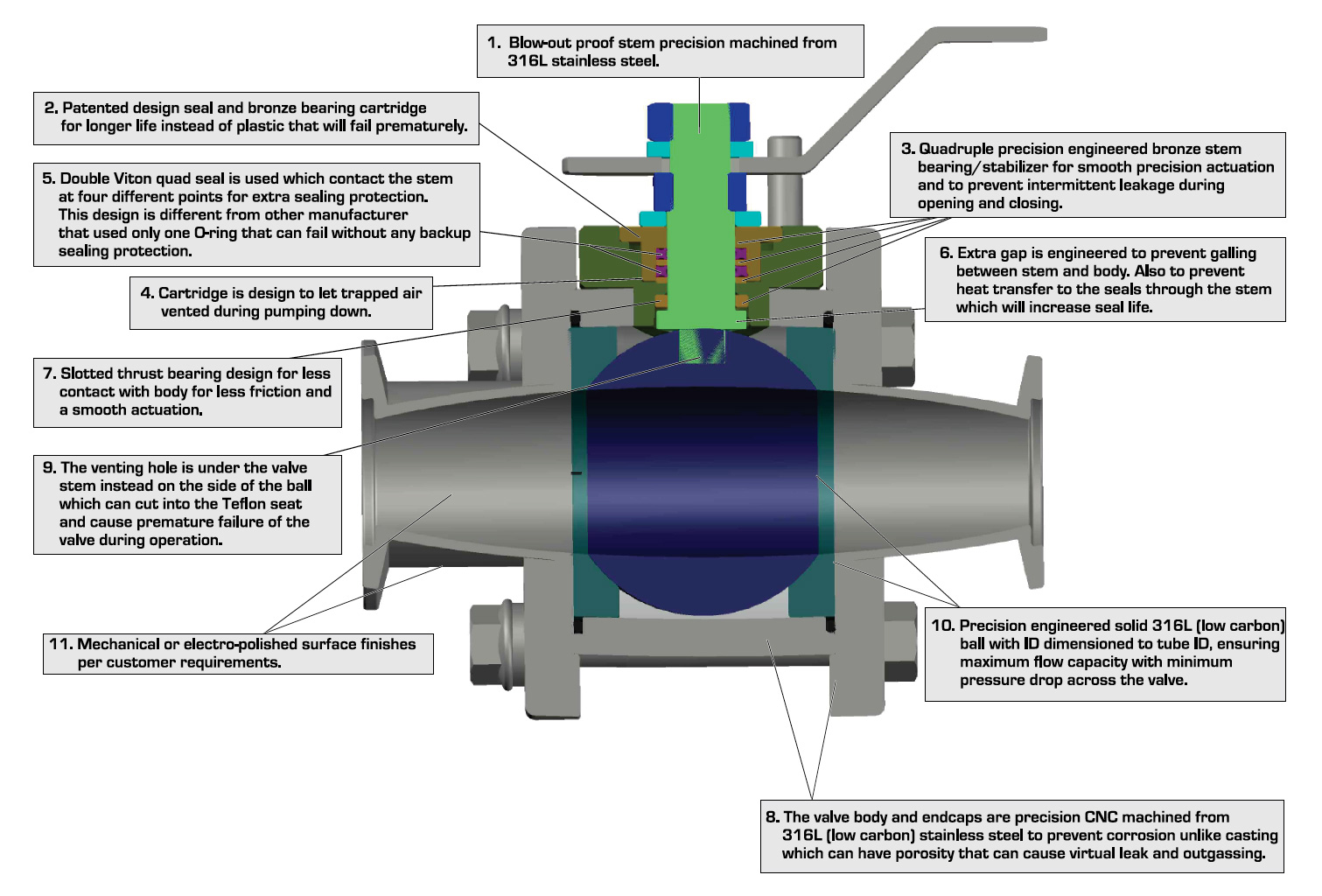

Ball Valve With Cavity Vent

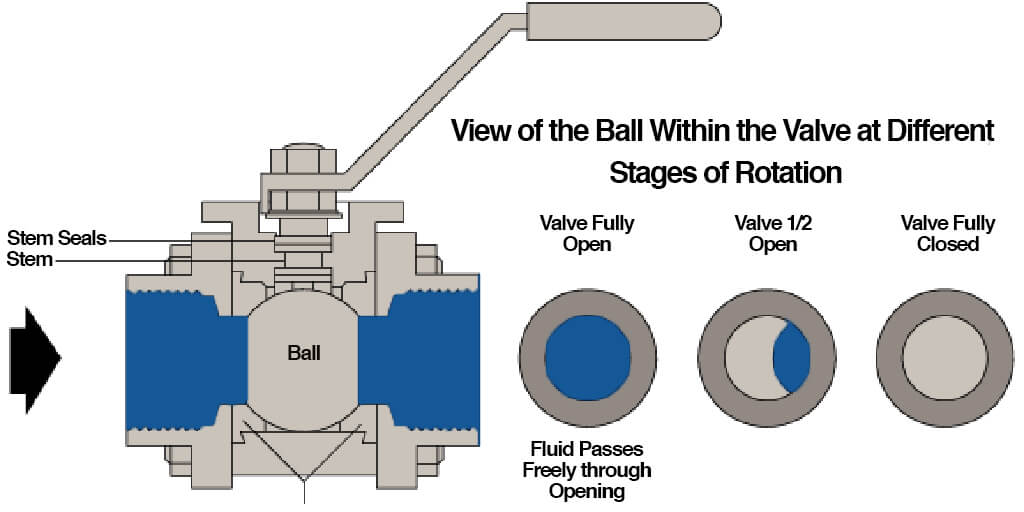

A ball valve is usually rotated 90 to open and close.

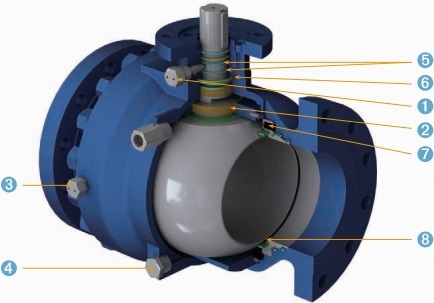

Ball valve with cavity vent. Process ball valve vent options 3 internal ball vents 2 way valves purpose the internal vent equalizes pressure in the ball and body to that of the system protecting the valve from temperature induced overpressurization. A ball valve is a type of valve that uses a spherical obstruction a ball to stop and start the hydraulic flow. Cavity vent orientation in lng service posted in industrial professionals. Figure 1 figure 2 pressure tight seat.

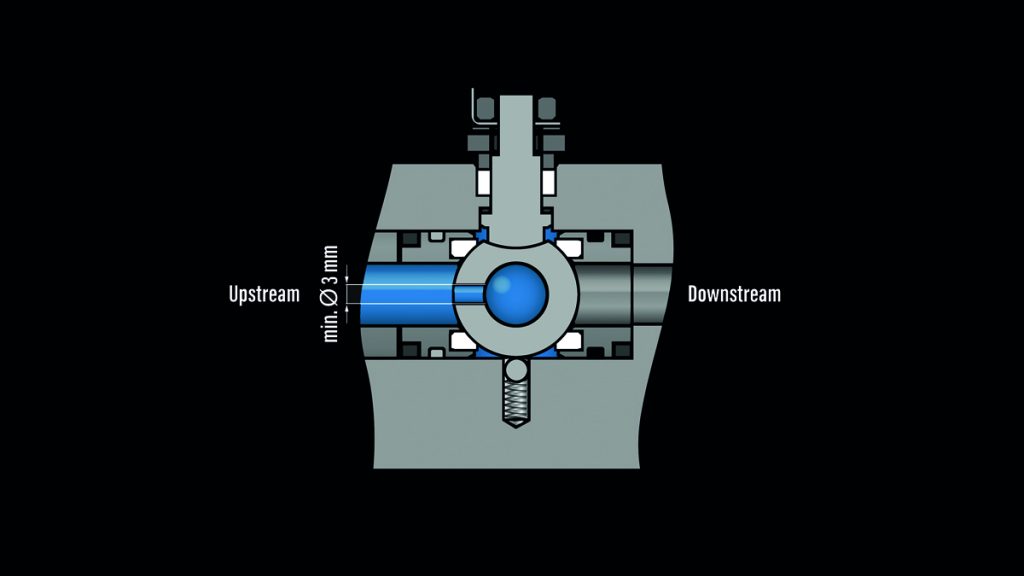

These include ball valves. What is a ball valve. The ball contains a vent passage that intersects the ball orifice at a 90 angle. The ball contains a vent that is isolated from the ball hollow to prevent continuous leakage from the body vent port when the valve is open.

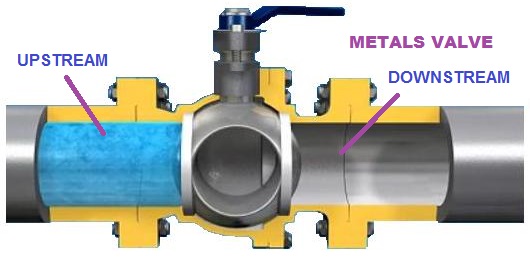

For the floating type soft seat ball valve and liquid fluid. In such an application it is important to know more than just the surface level distinctions and it is crucial to understand more importantly. Another important function of ball valve performance is the stem seal design. The downstream vent provides an exhaust path for the fluid downstream of the.

1 in case of temperature of fluid and atmosphere has some increasing for example water. It is one of the most widely used valve types. The vent allows trapped pressure to pass harmlessly away from the system directly into atmosphere when the valve is closed. A floating ball valve is a ball valve with an unsupported ball other than the two seats it rests on so that the ball moves in the valve cavity to help seal off the line pressure.

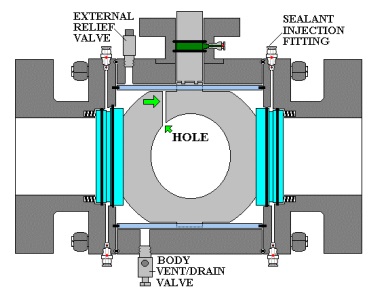

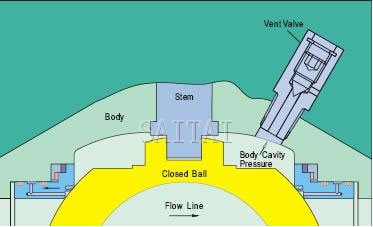

As you know the cavity vent is a small hole drilled in the ball of the valve so the lng trapped inside the ball can be relieved and will not cause. It allows bleeding of the cavity pressure through a drain or vent valve. While the difference between a vented ball valve and a standard ball valve may seem obvious on the surface of what constitutes their individual functions that distinction becomes far more critical when we introduce the factor of cryogenic processing. If the cavity does not have a vent the rise in pressure may cause damage on the valve.

This valve contains a body cavity vent which provides spontaneous relief of cavity pressure within a closed valve to the upstream high pressure side piping. The key to ball valve performance is the sealing design regardless of whether the seats are made of metal plastic or other material. If the liquid heats up it will increase the pressure in this cavity as a result of fluid expansion. The direction of pressure tightness is indicated by the single cast arrow on the side of the valve body as illustrated in figure 1.

Hello i am working in an lng project and have been tasked with marking up the ball valves in the project with the appropriate orientation of the cavity vent. 30 c depends on fluid and valve not operated for the time of increasing temperature.