Tapered Ball Nose End Mill Feeds And Speeds

Milling speeds and feeds charts the most important aspect of milling with carbide end mills is to run the tool at the proper rpm and feed rate.

Tapered ball nose end mill feeds and speeds. Tapered end mill usage can be tricky if the proper settings are not adhered to. With just a 3 angle per side feed rates may be increased by an average of 10 over a straight neck. All harvey tool products are fully supported with their own speeds feeds designed to provide the best tool possible for various applications. When considering an end mill with a straight reach versus the same end mill with a slightly tapered reach there are clear gains in tool performance and productivity.

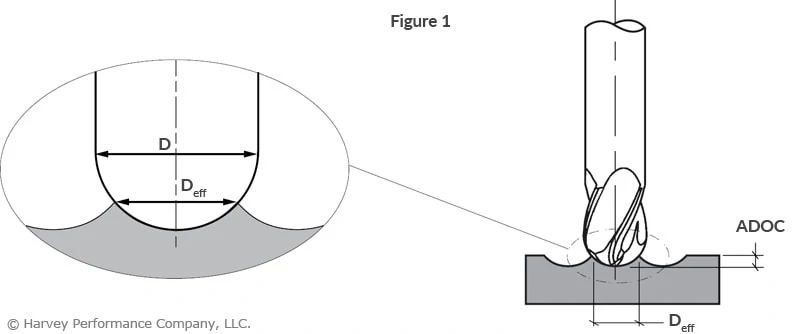

Ball nose finishing mills speed feed calculator instructions. Ball nose end mills are ideal for machining 3 dimensional contour shapes typically found in the mold and die industry the manufacturing of turbine blades and fulfilling general part radius requirements to properly employ a ball nose end mill with no tilt angle and gain the optimal tool life and part finish follow the 2 step process below see figure 1. With the widest selection of high speed steel tapered end mills available and an average 99 8 in stock status the conical tapered high speed steel end mill is the go to tool for unique machining challenges. In addition to our speeds feeds libraries you can also find specific running parameters directly on our product pages for every tool.

Tapered end mills high speed steel feed per tooth roughing and finishing. Speeds feeds solid carbide high performance end mills. Fill in the blocks shaded in blue with your application information. Tapered high speed steel.

Ball nose milling without a tilt angle. We have broken these recommendations down into material categories so you can make better decisions with how to productively run your end mills. Save time and money by downloading and printing the speeds and feeds table for your specific tool and simulate its running parameters and tool paths by accessing our complete library of simulation files. The calculator will automatically provide the necessary speed and feed in the green fields.

Feed inch tooth end mill diameter 1 8 3 16 1 4 3 8 1 2 5 8 3 4 1 recommendation for coated tools.