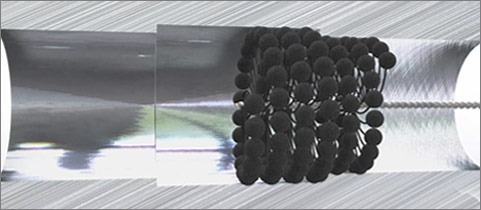

Ball Hone Vs Rigid Hone

The rigid stones do not conform very well to the existing bellmouth wear in the bore.

Ball hone vs rigid hone. For that 4 030 diameter use the 4 1 8 ball hone with 320 grit bg 418320. Flex hone tools don t require special training expensive equipment or complicated setups or clean ups. Flex hone tools have hundreds of cutting points for a full 360. What we call a rigid stone hone is the way to true up the cylinders only if a tweek is all that is needed.

For a used cylinder the dingleberry or ball hone is the proper tool. A long lasting diamond abrasive is embedded in balls at the ends of flexible spindles that press against the inside of a cylinder to remove material and leave a smooth even finish. This in turn breaks the balls which will then gouge the cylinder walls instead of leaving a relatively even surface. Cutting points and crosshatching.

Flex hone cylinder ball hone 49 51mm for suzuki rm80 1977 1985. This is a 4 1 8 ball hone with 320 grit. The ball hones follow the wavy shit that is worn in the block. Use lots of honing oil and hone for 10 to 45 seconds per cylinder.

These hones are avail many sizes. If you have any other questions feel free to call our tech services department at 800 533 8010. Run this tool at around 350 400 rpms. Free shipping on orders over 25 shipped by amazon.

The rigid stone hone is gear fed like a rack and pinion feed for the stones. Get it as soon as fri may 29. I saw a detroit sleeve that had been ball honed not pretty. You could see and feel swirls and slight grooves where the hone was run in and out.

3 stone hone vs a flex hone the biggest advantage of a stone hone is that it will cut large amounts of material. Most oems and ring manufacturers state the angle of the scratches in the crosshatch pattern should be about 27 45 degrees with 45 degrees the optimum. These hones are slightly oversized to maximize contact with the work surface. The 16000 hone tool range is a combination of adjustment ans stone usage.

Of course if it is to far out shape the bore job is next. Today we are going to discuss the differences between the brm flex hone or ball hone and the 2 or 3 stone hone. Use with portable drills drill presses and cnc machines. Lisle cylinder hones are a rigid micrometer controlled pressure hones.

A ball hone will catch in the ports. Rigid hones have only two or three stones. Brush research ch c large chamfer flex hone silicon carbide 3 4 diameter 180 grit pack of 1 4 1 out of 5 stars 3. The 15000 hones have several different racks that must be interchanged to reach the wide range of use.

The resulting cross hath angle produced by the flex hone or a three spring hone or a rigid hone for that matter is strictly a function of stroke rate versus rpm.