Ball Valve Greasing Procedure

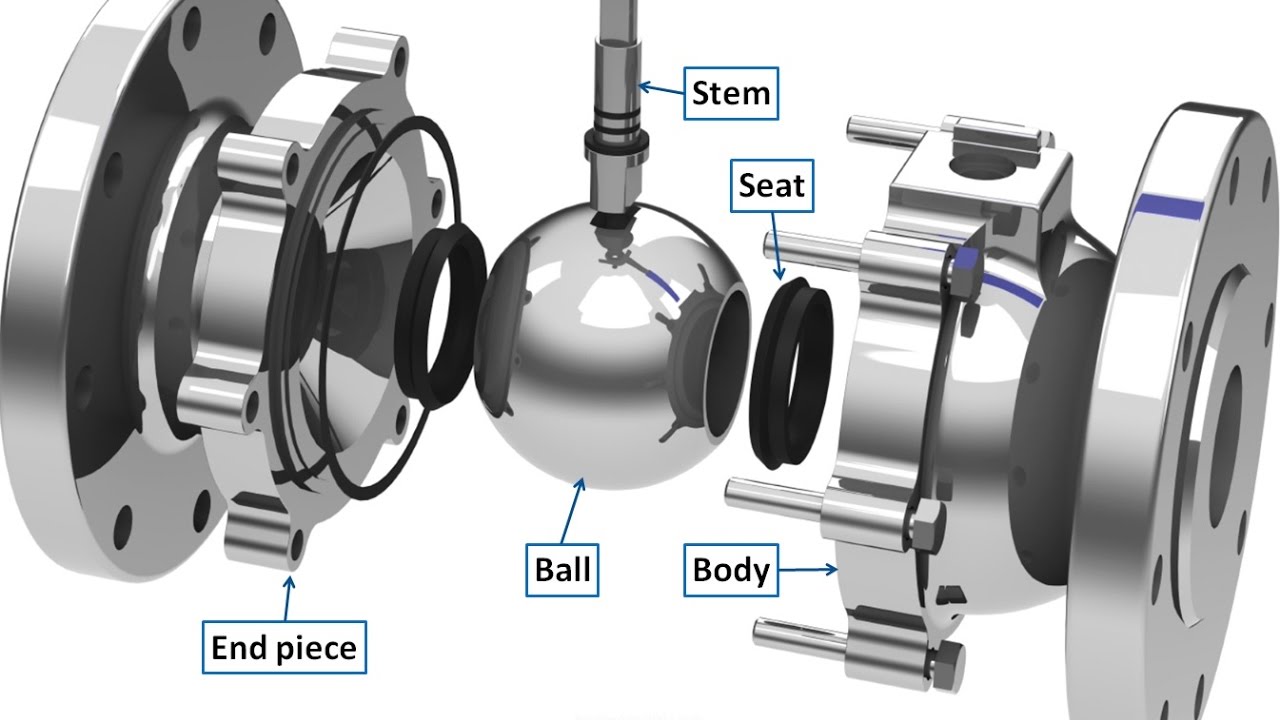

Determine the number of sealant injection ports on the valve seats.

Ball valve greasing procedure. If possible operate the valve and determine its condition. Place the valve in either the fully open or the fully closed position. Plug valve greasing is a regular maintenance procedure that should be done frequently to avoid wear and malfunction in high pressured plug valves. Sometimes it takes two people and an 8 foot cheater pipe to operate a 6 inch valve.

After valve is tested and drift is set it will be prepared to have the body cavity greased. Open valve with 1 inch opening in bore. Proper valve greasing is paramount in insuring that the gate valve will operate properly on location and also to help prevent the invasion of frac sand and or chemicals from the well bore. The manufacturer tests each valve according to specifications as detailed in api 6d or similar standard then issues a performance certificate.

The sealweld valve training and safety seminar is a comprehensive training program that teaches operations personnel a safe and effective method of servicing on line valves. Quantities required to top up any valve can vary greatly depending on the valve size design cycle frequency service conditions and riser pipe height if applicable. The fluid does not disrupt the operation of the seat and seal arrangement. The seminar provides useful information that will prolong valve life.

B70sis a synthetic ball valve. Procedures for injecting val tex valve flush into ball valves 1. Sometimes the valve won t shut off at all. B70 is a standard service ball valve lubricant.

Routine maintenance often consists of topping up the lubricant sealant in the valve sealant system the sealant system is a network of grooves and channels inside the valve leading to seal points around the ball gate or plug. A fluid type lubricant such as b70 or b70sshould be used to routinely flush and lubricate the valve. Suppose this is an isolation valve. Over greasing can be just as dangerous as under greasing leading to a high pressure system and ultimately system failure.

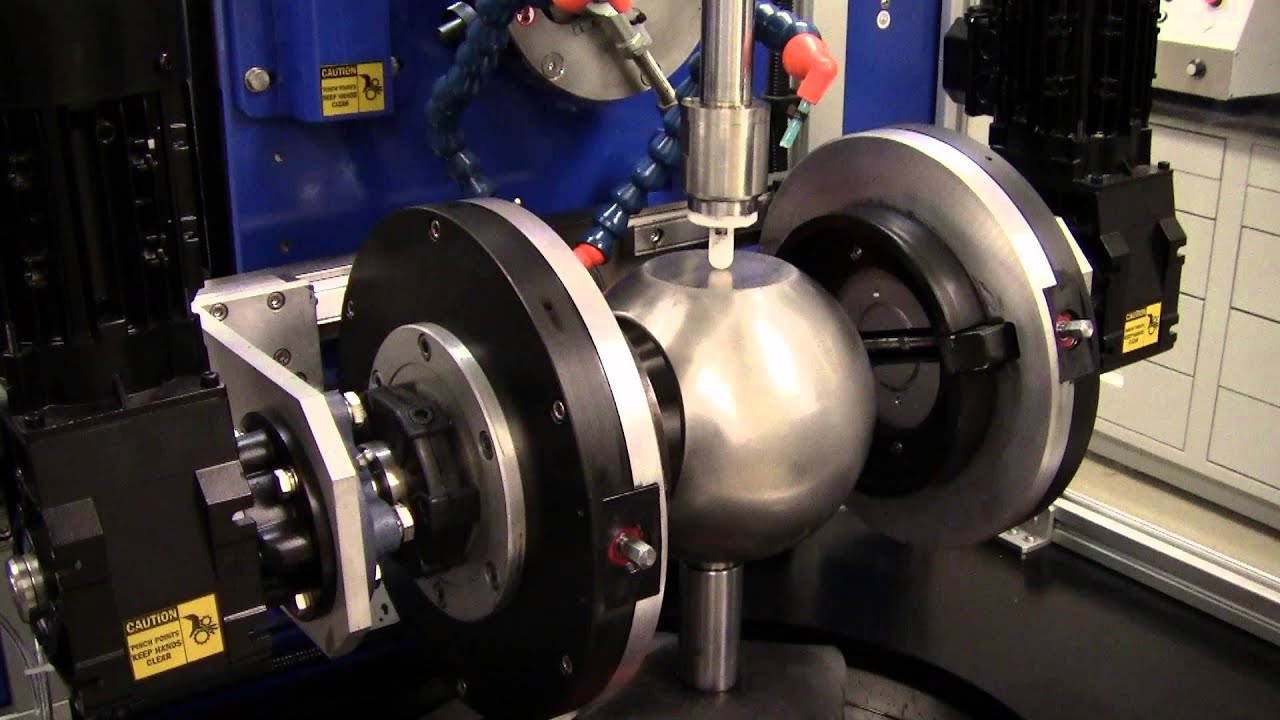

Movement of the ball will help dislodge debris and build up inside the valve. Procedures for preventative maintenance treatment of pipeline ball valves in natural gas pipelines background pipeline ball valves are produced by a variety of manufacturers around the world.