Ball Valve Weights And Dimensions

Long life and safe operation in tough services from cryogens to highly corrosive fluids these are the hallmarks of our comprehensive and respected ball valve portfolio.

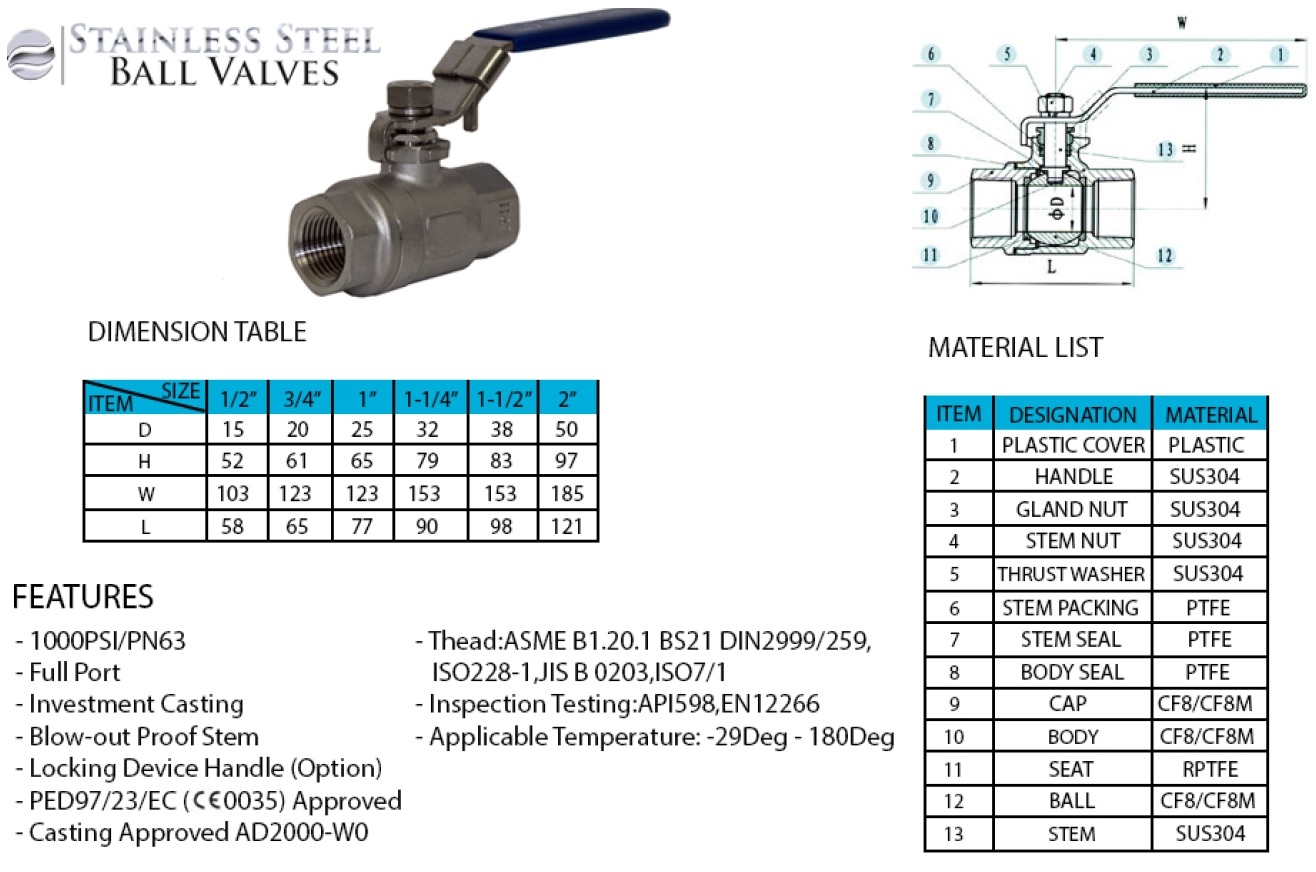

Ball valve weights and dimensions. Standard e series flanged ball valves with certain body seat and trim materials handle low pressure saturated steam services to 150 psig at 366ºf and when supplied in the thermopac version up to 250 psig at 406ºf. Guided ball full trunnion. 600 cwp 150 swp full port threaded ends figure 9201 600 cwp 150 swp full port solder ends figure 9202. 1 inch 2 inch 3 inch 4 inch ball valve dimensions.

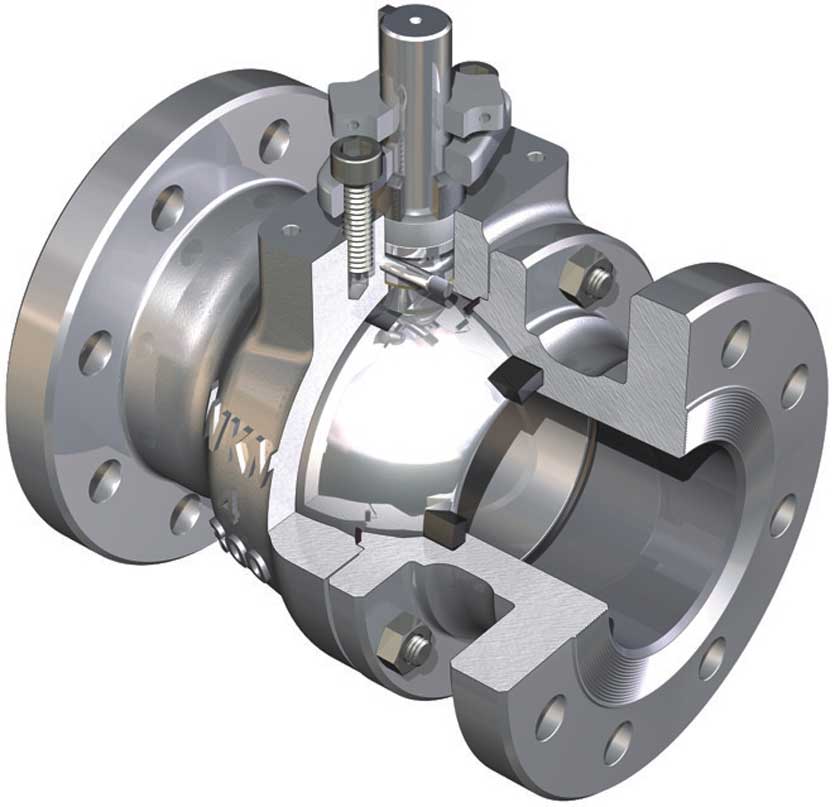

Ball valve dimensions class 150 class 800 class 3000 ball valve pressure rating chart 3 way ball valve dimensions threaded ball valve dimensions. The trunnion ball valve is a form of quarter turn valve which uses a hollow perforated and fixed supported ball to control flow through it. We provide large diameter valves for use in natural gas lng crude oil and refined products transmission lines as. Technical g a drawing dimensions weight details of api 600 gate valves 150lb 300lb 600lb 900lb 1500lb and 2500lb.

Maximum safety and environmental protection are the driving factors in every design achieved through corrosion resistant materials fire safe testing blowout proof stems and tight shut off features. Crane ball valves dimensions and weights. Cameron fully welded ball valve is commonly selected for a number of applications including. Grove b4 b5 b7 side entry ball valves features and benefits cameron s valves measurement business segment is a leading provider of valves valve automation and measurement systems to the oil and gas industry.

One of the most trusted valves in the petroleum industry it combines the strength of forged components with a lightweight and compact spherical design. 30 inch 36 inch 14 inch 24 inch 1 5 inch ss ball valve price list india ball valve price list in india ss316 ball valves price ss304 ball. E series flanged ball valves have a 1 8 hole in the ball stem slot to ensure cavity pressure relief in the open position. Design as per bs5351 ansi b16 34 iso 17292 api 6 d upon request iso 5211 top flange fire safe construction certified as per bs 6755 part 2 api 6fa api 607 and iso 10497 ressure testing according api 598 iso 5208 and p api 6d upor request floating ball.