Carbide Ball Nose End Mill Speeds And Feeds

Aluminum aluminum alloys 2024 t4 t6 2014 6061 t6 t651.

Carbide ball nose end mill speeds and feeds. Sfm spindle speed compensates for machine max. Rpm feed per tooth desired chip thickness. Simply search for your tool number and then click on the orange speeds feeds tab next to the product table. We have broken these recommendations down into material categories so you can make better decisions with how to productively run your end mills.

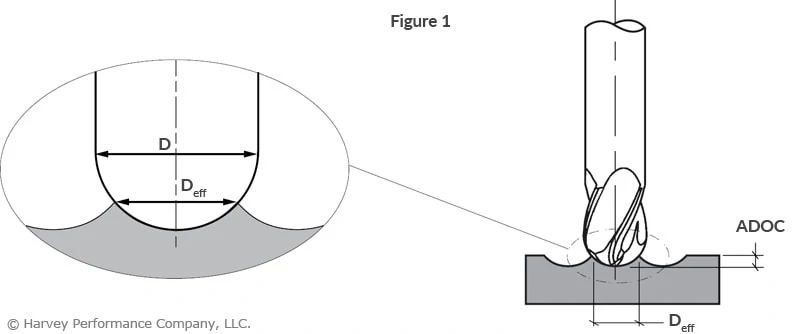

Save time and money by downloading and printing the speeds and feeds table for your specific tool and simulate its running parameters and tool paths by accessing our complete library of simulation files. Made of solid carbide these end mills are harder stronger and more wear resistant than high speed steel for the longest life and best finish on hard material. Ipm feed per tooth adjusted to axial depth of cut d d 2. The end of this tool is ground with a full radius equal to half of the tool diameter and the edges are center cutting.

In addition to our speeds feeds libraries you can also find specific running parameters directly on our product pages for every tool. Speed and feed calculators ball mill finish calculator part spacing calculator g and m code characters standard end mill sizes standard drill sizes drill. They can be single end or double end and they can be made from solid carbide or various compositions of high speed steel. We provide the equations to calculate speed and feed.

Ipm feed rate adjusted to axial depth of cut if d d 2. Fpt feed rate w o adjustment to axial depth of cut. All harvey tool products are fully supported with their own speeds feeds designed to provide the best tool possible for various applications. Feed inch tooth end mill diameter 1 8 3 16 1 4 3 8 1 2 5 8 3 4 1 recommendation for coated tools.

Speeds feeds solid carbide high performance end mills. Use kodiak cutting tools carbide end mill speeds and feeds for recommended values for uncoated tools. A ball end milling cutter is also known as a ball nose mill. Milling speeds and feeds charts the most important aspect of milling with carbide end mills is to run the tool at the proper rpm and feed rate.

Martin chick associates cnc programming services.