Spring Loaded Ball Valve Symbol

Full port valves do not restrict flow.

Spring loaded ball valve symbol. Spring close lever handles automatically close when the lever is released. Type of valve employed depends on nature of fluid flow control required operating pressure and temperatures as well as surround atmosphere. Many types of valves are required in a process plant for flow regulation or on off purpose. Most competitors use standard port valves or reduced port valves so you need to hold the handle open longer with competitors valves.

Grease pump the grease pump has 2 valves often spring loaded ball valves that operate in a seat. A ball check valve is a check valve in which the closing member the movable part to block the flow is a ball. Standard port valves slightly restrict flow. The valve starts to pass fluid at a pressure equivalent to the spring cracking pressure level.

Highly simplified and idealized spring loaded check valve design and operation a miniature spring loaded check valve is usually installed in line with the process piping. Symbol for 3 port valve with 2 positions. The spring pushes from the side that is drawn on and will return the valve back to its failsafe position. The graphical symbol for these valves is a spring loaded ball and a seat as shown below.

Symbol for 2 port valve with two positions one position valve open with flow in both directions or valve closed with both ports blocked. Our deadman handle spring return ball valves are full port. The anti scald mixing valve is recommended if the dhw temperature is set above the factory setting of 119 f. Most of our deadman handle ball valves use self adjusting packings with belleville washers.

P ids piping instrumentation diagrams and p id valve symbol library posted on december 21 2017 by jeff rinker a piping and instrumentation diagram p id is a graphic representation of a process system that includes the piping vessels control valves instrumentation and other process components and equipment in the system. The most significant safety aspect common to these tsvs are. This body has a cross sectional element the seat with a passage or hole through it. Flow coefficient cv is the amount of water in gallons per minute at 60â f that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

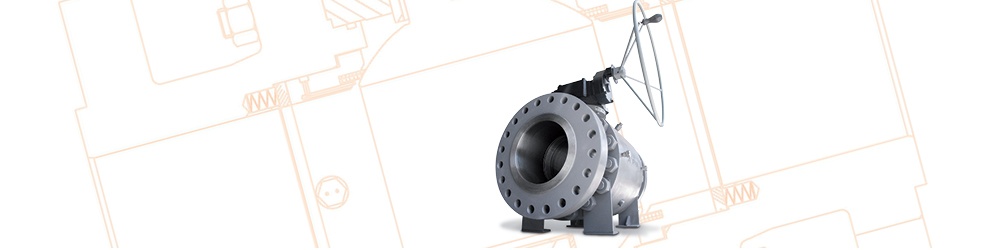

The alternative is standard flanges with full port ball valves and a separate flow check valve. This passage is oriented across the flow through the valve. The valve body is hollow. An internal spring loaded ball valve primary seal spring to close.

For those designs without a spring reverse flow is required to move the ball toward the seat and create a seal. Direct operated free flow no flow a light spring holds the valve poppet in its normally closed position. Here is a list of symbols for various types of valves used in process industry.