Ball Mill Questions Critical Speed

When using a ball nose end mill the most critical area of the cutting edge is the tool centre where the cutting speed is close to zero which is unfavourable for the cutting process chip evacuation at the tool centre is critical due to the narrow space at the chisel edge.

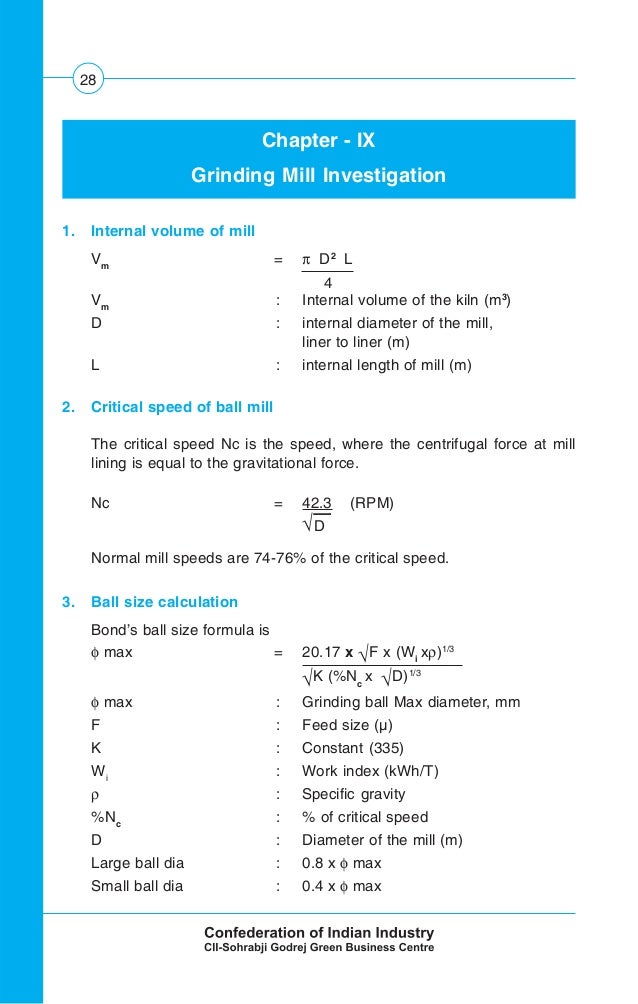

Ball mill questions critical speed. A ball mill critical speed actually ball rod ag or sag is the speed at which the centrifugal forces equal gravitational forces at the mill shell s inside surface and no balls will fall from its position onto the shell. Media o d with dimensions in inches. The faster the mill speed the greater the wear on the rods and liners. In most cases the ideal mill speed will have the media tumbling from the top of the pile the shoulder to the bottom the toe with many impacts along the way.

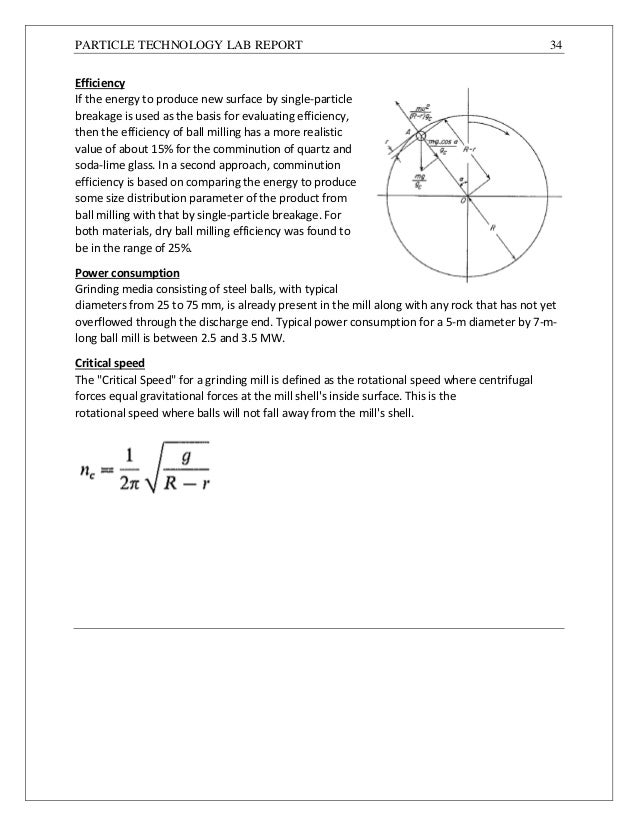

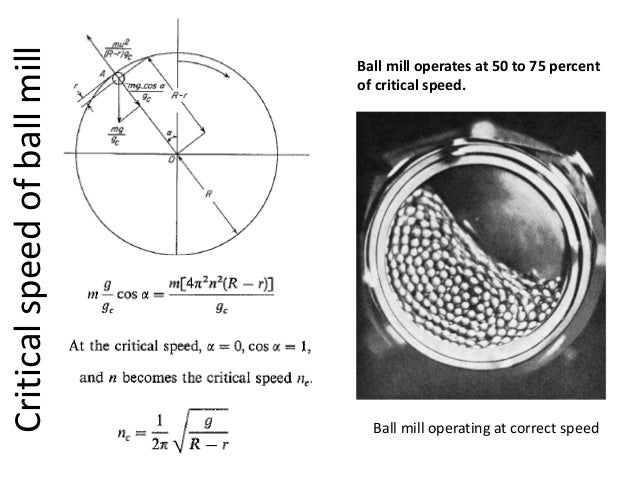

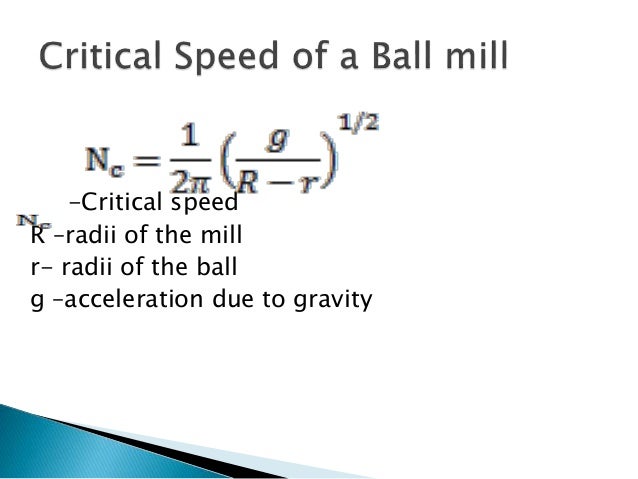

Use our online formula the mill speed is. The ideal mill speed is usually somewhere between 55 to 75 of critical speed. At the top of the cycle 0 and fc fg 8 5 mp 2 cdm 2 mpg 8 6 c 2g dm 1 2 8 7 the critical speed is usually expressed in terms of the number of revolutions per second nc c 2 1 2 2g dm 1 2 2 9 81 1 2 2 d1 2 m 0 705 d1 2 m. Rod mills speed should be limited to a maximum of 70 of critical speed and preferably should be in the 60 to 68 percent critical speed range.

Ball mills are generally used to grind material 1 4 inch and finer down to the particle size of 20 to 75 microns. 2012 11 26rod mills how do they work the critical speed is used for the determination of ball mill ideal operating speed. The point where the mill becomes a centrifuge is called the critical speed and ball mills usually operate at 65 to 75 of the critical speed. So the general rule of thumb for rod mills is to operate no faster.

A ball mill critical speed actually ball rod ag or sag is the speed at which the centrifugal forces equal gravitational forces at the mill shell s inside surface and no balls will fall from its position onto the shell. The critical speed of the mill c is defined as the speed at which a single ball will just remain against the wall for a full cycle. The imagery below helps explain what goes on inside a mill as speed varies. Also the height of the lifter bar in configuration 3 was changed to observe the trajectory.

But for comparison rod mills would operate between 50 to 95 of the critical speed. The imagery below helps explain what goes on inside a mill as speed varies. The face angle was varied from 90 to 111 degrees for the three types of configuration 1 2 and 4 as shown in the figure.